About the author: Adam Toth

Adam Toth owns Tag Frames, a Queensland-based firm that crafts steel house frames. Holding a QBCC licence, he is acknowledged for his specialisation in steel framing for homes, with a track record of numerous successful steel frame projects.

Can I drill into metal studs?

Reading Time: 6 minutes and 5 seconds

Working with metal studs is a common task in construction, and I’ve seen firsthand just how popular they’ve become, especially here in Queensland. Whether you’re dealing with stainless steel wall frames in commercial projects or steel house frames for residential builds, metal studs are incredibly durable and reliable.

But one question I often get asked by both homeowners and professionals alike is: Can I drill into metal studs without weakening them? The short answer is yes, but like many things in construction, it requires the right technique, the correct tools, and some careful consideration to ensure you’re not compromising the integrity of the structure.

Through years of experience in the field, I’ve learned that understanding the proper approach when drilling into metal studs makes all the difference. Whether you’re mounting a TV, hanging a mirror, or installing shelving, let me walk you through how to safely and effectively drill into metal studs without worrying about weakening them.

Table of Contents

Is drilling metal studs possible?

The answer is a resounding yes!

When I first started working with steel wall frames on larger projects in Queensland, I quickly learned they require a different approach than traditional timber framing. Steel studs are incredibly strong and durable, but you need to use the right techniques to ensure a safe and successful installation. With the proper tools and methods, drilling into metal studs is straightforward and can be done without compromising the integrity of the steel frame.

Here’s what you need to know when drilling into metal studs:

| Factors | Recommendations |

| Drill Bits | Use carbide-tipped, cobalt, or titanium bits designed for metal. |

| Pilot Holes | Always drill pilot holes, especially for heavy fixtures. |

| Screw Type | Use self-drilling screws for lighter items and fine/coarse-thread screws for heavy-duty applications. |

| Drill Speed | Maintain 700-1,000 RPM to prevent overheating the bit. |

| Drill Location | Drill at the centre of the stud, not near the edges. |

My Experience with Metal Studs in Queensland

I’ve worked with metal studs for many years, and it’s especially crucial in Queensland, where the climate can take a toll on materials if you don’t choose the right ones. In one particular job, we installed stainless steel wall frames in a coastal building. The client wanted to mount some heavy fixtures, and I knew that using the wrong screws or drill technique could result in corrosion or structural failure, particularly with the high humidity in the region.

This is why I always emphasise the importance of using stainless steel or coated screws to prevent rust. In my experience, using the right fasteners can make or break a project—literally.

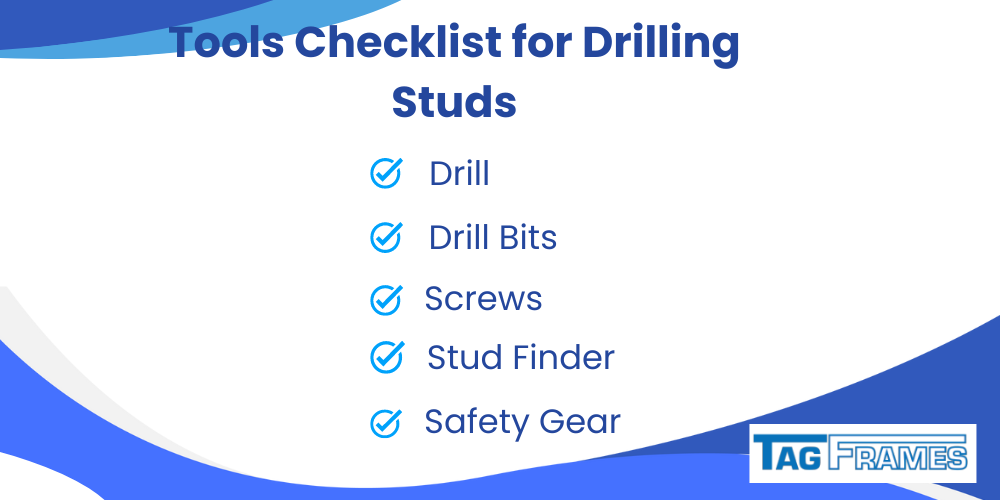

Tools You’ll Need for Drilling into Metal Studs

Having the right tools on hand is essential. I’ve found that using subpar equipment only leads to frustration and rework down the line. Here’s a breakdown of what I always make sure to have on-site:

- Drill: A high-quality drill with variable speed settings is a must for precise control.

- Drill Bits: Always use carbide-tipped, cobalt, or titanium drill bits. These materials are built to withstand the heat generated from drilling into metal.

- Screws: Choose self-drilling screws for light-duty tasks, fine-thread screws for thin studs, and coarse-thread screws for heavy-duty applications.

- Stud Finder: This tool is non-negotiable for locating the centre of the stud.

- Safety Gear: Don’t forget safety glasses and gloves. I’ve learned this the hard way—metal shavings can be nasty. Remember always to follow the standards set by Safe Work Australia!

How to Drill into Metal Studs Without Weakening Them

Here’s how you can confidently drill into metal studs without compromising their integrity.

- Locate the Stud: I always use a stud finder to ensure I’m drilling into the centre. Metal studs are usually spaced 12, 16, or 24 inches apart. Drilling off-centre can weaken the frame.

- Choosing the Right Drill Bit: In my experience, carbide-tipped or cobalt bits are a must. These durable bits make light work of drilling through tough materials like stainless steel.

- Drill a Pilot Hole: For heavier loads, I always drill a pilot hole first. This step guarantees the screw will seat properly and reduces the chance of mistakes.

- Drill Speed: I’ve found that maintaining a speed of 700–1,000 RPM ensures the bit doesn’t overheat and cuts into the metal smoothly.

- Use the Correct Screws: Self-drilling screws are great for light applications, but for heavier items, I switch to fine-thread screws for thinner studs or coarse-thread screws for thicker, more robust ones.

How large of a hole can I drill in metal studs?

People often ask me how big a hole can be drilled into metal studs without messing things up. Well, it depends on the type of stud. If it’s load-bearing, you don’t want to go over 40% of the stud’s width, as per the National Construction Code (NCC). But for non-load-bearing studs, you’ve got a bit more leeway—up to 60% of the width. Also, always keep the hole at least 5/8 inches away from the edge to avoid weakening it.

I remember working on this big commercial job where I had to be extra careful. I’ve seen things go sideways when people over-drill and trust me, it’s not pretty. Always stick to these guidelines if you want to keep everything safe and sturdy.

Will drilling weaken metal studs?

Ever wondered if drilling weakens metal studs? From my own hands-on experience, the answer is no—at least if you’re doing it right! Drilling in the centre and using the right tools keeps the stud strong. But if you get too close to the edge or make the hole too big, that’s when things can get shaky. It’s all about being precise and mindful.

Here’s a Tip: Drilling a pilot hole actually helps keep the stud strong. It prevents weakening and keeps everything stable, even with a load.

Your Go-to Partner for Steel Wall Frames

Drilling into metal studs is not only possible but essential in modern construction projects, especially when working with high-quality materials like steel frames. By following the correct techniques—selecting the right drill bits, screws, and ensuring proper alignment—you can confidently maintain the structural integrity of your steel frames. Whether you’re working on a residential build or a commercial project, choosing the right materials makes all the difference.

If you’re looking for durable, reliable, and corrosion-resistant steel house frames, wall frames, or steel trusses, Tag Steel Frames offers premium solutions tailored to your needs. Contact us today to learn how we can support your next project with industry-leading steel frame systems!

FAQ

Identifying load-bearing walls in your steel wall frame is essential before making any modifications. Start by examining the foundation—walls that connect directly to the concrete slab or foundation are often load-bearing. Look for thick steel beams that stretch across multiple floors, as these beams typically support the structure’s weight. Check the floor joists as well—if they meet a wall perpendicularly, that wall is likely load-bearing. If you’re unsure, it’s best to consult a professional to avoid compromising the integrity of the building. We can help guide you through the process and provide expert advice for your steel framing needs in Queensland!

Steel wall frames with metal studs offer several advantages over traditional timber frames. Steel studs are lighter and easier to install, making the process quicker and less labour-intensive. They also remain straight during transportation, ensuring precise alignment during installation. Unlike timber, steel is resistant to pests like termites and doesn’t warp or rot, which reduces the need for ongoing maintenance. Additionally, steel wall frames provide superior fire resistance, making them a safer option for both residential and commercial builds. If you’re considering switching to steel, we offer high-quality solutions designed for durability and ease of installation.

Yes, metal studs in steel wall frames are well-suited for high-moisture environments. Steel, particularly when galvanised or coated, resists corrosion better than timber, making it a reliable choice in humid or coastal regions. Metal studs are also immune to termites, which is another advantage over wood in damp areas. Their durability ensures that steel wall frames remain structurally sound despite challenging environmental conditions. For coastal or high-humidity projects, we provide you with steel frame solutions built to withstand Queensland’s toughest climates.